Establishing a PVC seals factory is a complex and multifaceted endeavor that involves a wide range of processes, technologies, and considerations. This very long description outlines the key aspects and steps involved in setting up a PVC seals manufacturing facility.

1. Market Research and Feasibility Study:

Before venturing into the PVC seals manufacturing business, extensive market research and a feasibility study are crucial. This includes analyzing market demand, identifying competitors, and understanding potential customers’ needs and preferences. This research helps in determining the viability of the business and crafting a successful business plan.

2. Business Plan Development:

A comprehensive business plan is essential for securing financing, setting goals, and outlining the roadmap for the factory. This plan should cover aspects such as production capacity, sales and marketing strategies, equipment and technology requirements, staffing needs, and financial projections.

3. Legal and Regulatory Compliance:

Compliance with local, regional, and national regulations and standards is paramount. This includes obtaining the necessary permits, licenses, and certifications for operating a PVC manufacturing facility. Compliance with environmental regulations is particularly critical due to the nature of PVC production.

4. Location Selection:

Choosing an appropriate location for the factory is a strategic decision. Factors to consider include proximity to suppliers, access to transportation routes, availability of utilities, and compliance with zoning regulations. The chosen location should also allow for future expansion if needed.

5. Facility Design and Construction:

The factory’s design should optimize workflow and production efficiency. Key considerations include the layout of production lines, storage areas, quality control zones, and administrative offices. The construction process involves building or retrofitting the facility to meet industry standards and safety requirements.

6. Equipment Acquisition:

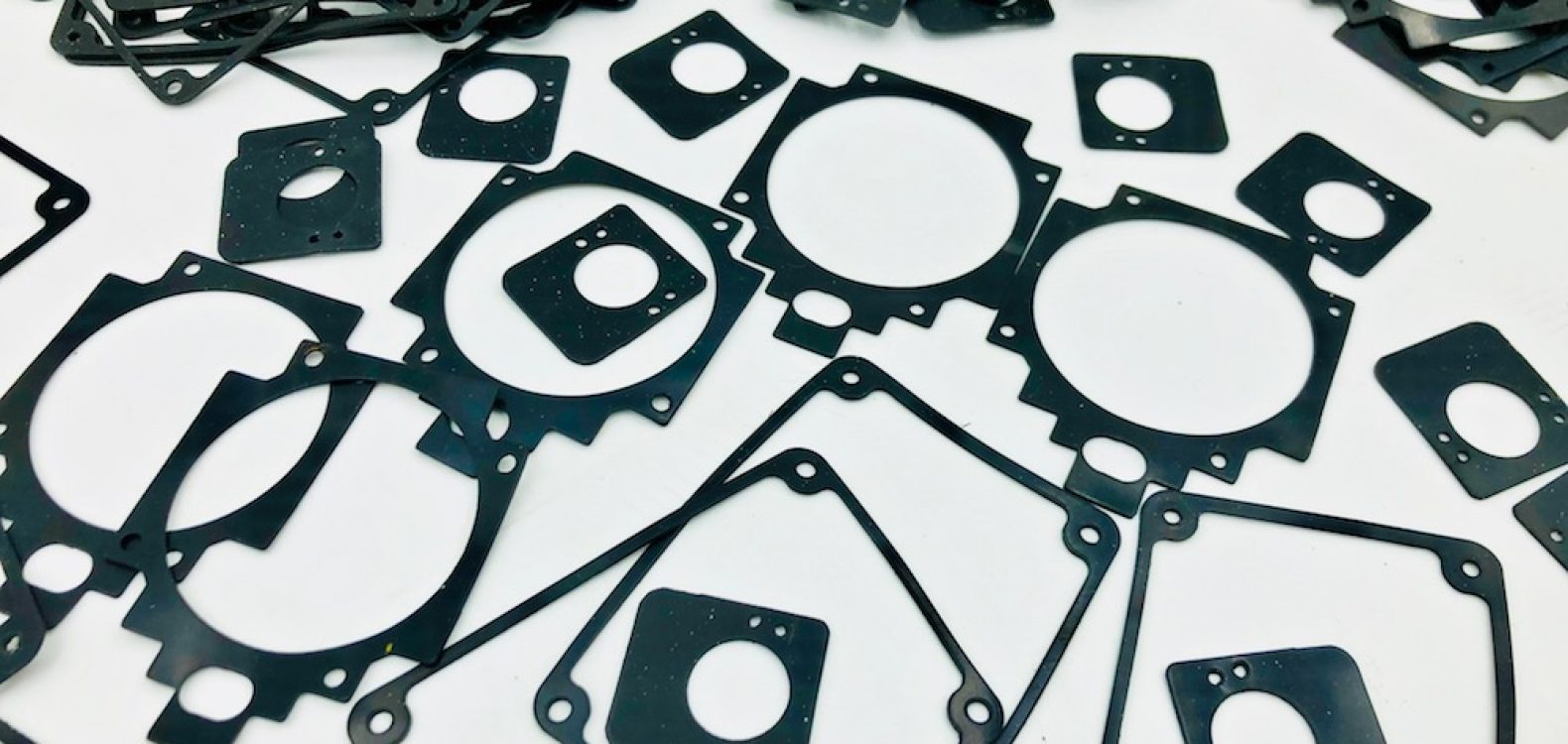

Procuring the necessary machinery and equipment is a critical step. This includes extrusion machines, molds, mixing equipment, cutting and finishing machines, and quality control instruments. The choice of equipment should align with the intended scale of production and product specifications.

7. Raw Material Sourcing:

PVC seals are typically made from PVC resin, plasticizers, stabilizers, and additives. Establishing reliable sources for high-quality raw materials is essential for consistent product quality. Negotiating favorable supply contracts can also help with cost control.

8. Workforce Recruitment and Training:

Building a skilled and dedicated workforce is crucial. Recruitment should focus on hiring operators, technicians, engineers, quality control personnel, and administrative staff. Training programs should be implemented to ensure that employees are proficient in their respective roles.

9. Production Processes:

PVC seal manufacturing involves several stages, including:

- PVC Resin Mixing: PVC resin is mixed with plasticizers and additives to create a flexible PVC compound.

- Extrusion: The PVC compound is melted and forced through extrusion dies to form profiles of the desired shape and size.

- Cooling and Cutting: The extruded profiles are cooled and then cut into the desired lengths.

- Quality Control: Rigorous quality control measures are implemented to ensure product consistency and compliance with specifications.

- Packaging: Finished PVC seals are packaged and prepared for distribution.

10. Quality Assurance and Testing:

Implementing a robust quality control system is essential to maintain product integrity. This includes regular testing for physical properties, dimensional accuracy, and resistance to environmental factors.

11. Marketing and Sales:

Developing a strong brand and marketing strategy is crucial for gaining market share. Building relationships with distributors, wholesalers, and end-users is vital for sales growth.

12. Sustainability Initiatives:

In today’s environmentally conscious world, incorporating sustainability practices is essential. This may involve recycling PVC waste, reducing energy consumption, and adopting eco-friendly manufacturing processes.

13. Distribution and Logistics:

Establishing an efficient distribution network ensures that PVC seals reach customers promptly and in good condition. Consideration should be given to transportation, warehousing, and inventory management.

14. Financial Management:

Effective financial management, including budgeting, cost control, and financial reporting, is essential for the long-term sustainability of the factory.

15. Continuous Improvement:

To stay competitive and adapt to changing market conditions, ongoing research and development, product innovation, and process improvement are necessary.

16. Health and Safety Measures:

Prioritize the safety and well-being of employees by implementing strict health and safety protocols. This includes training on handling chemicals, operating machinery, and responding to emergencies.

17. Environmental Responsibility:

Develop and adhere to eco-friendly practices and waste management systems to minimize the environmental impact of PVC production.

Setting up a PVC seals factory is a complex and resource-intensive undertaking, but with meticulous planning, adherence to industry best practices, and a commitment to quality, it can be a successful and profitable venture. Additionally, staying abreast of industry trends and consumer demands is vital to maintain a competitive edge in the market.