GRP (Glass Reinforced Plastic) pipe seals, also known as fiberglass pipe seals, are essential components used in the construction and maintenance of GRP piping systems. GRP pipes are widely used in various industries due to their corrosion resistance, durability, and lightweight properties. GRP pipe seals are designed to ensure the integrity and reliability of these pipes by providing effective sealing and protection against external factors. In this comprehensive description, we will explore the key features, applications, manufacturing processes, and advantages of GRP pipe seals.

Key Features of GRP Pipe Seals:

- Corrosion Resistance: GRP pipes are highly resistant to corrosion from chemicals, saltwater, and environmental elements. GRP pipe seals are engineered to complement this property, ensuring long-lasting sealing performance.

- Sealing Efficiency: These seals are designed to provide a reliable and tight seal, preventing leaks and minimizing fluid or gas loss in the piping system.

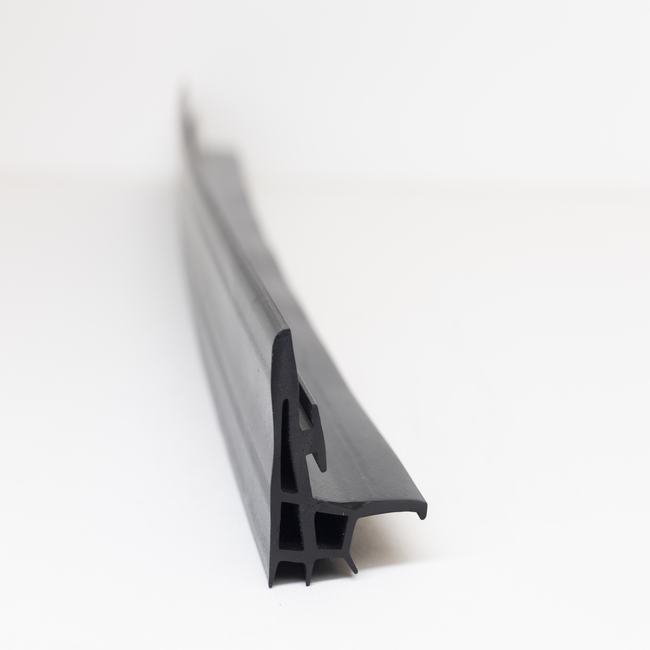

- Flexibility: GRP pipe seals are flexible and can adapt to the varying shapes and dimensions of GRP pipes, allowing for versatile application.

- High-Temperature Resistance: They can withstand a wide range of temperatures, making them suitable for both hot and cold fluid conveyance systems.

- Chemical Compatibility: GRP pipe seals are compatible with a range of chemicals, making them suitable for use in industries such as chemical processing, water treatment, and wastewater management.

- UV Resistance: They are resistant to UV radiation, making them suitable for outdoor and exposed piping systems.

Applications of GRP Pipe Seals:

- Water and Wastewater Treatment: GRP pipe seals are commonly used in water and wastewater treatment plants for sealing connections between pipes, tanks, and other equipment.

- Chemical Processing: Industries that deal with corrosive chemicals rely on GRP pipes and seals to transport fluids safely and efficiently.

- Oil and Gas: In the oil and gas sector, GRP pipes and seals are used for offshore and onshore applications, including pipelines, platforms, and refineries.

- Industrial Manufacturing: GRP pipe seals find use in various industrial processes, including food and beverage manufacturing, pulp and paper production, and more.

- Marine Applications: Due to their corrosion resistance and durability, GRP pipe seals are employed in shipbuilding and marine infrastructure.

- Infrastructure Projects: GRP pipes and seals are used in civil engineering projects such as bridges, tunnels, and drainage systems.

Manufacturing Processes:

GRP pipe seals are typically made through a combination of manual and automated processes:

- Material Selection: High-quality fiberglass-reinforced plastic materials are chosen for their specific application requirements.

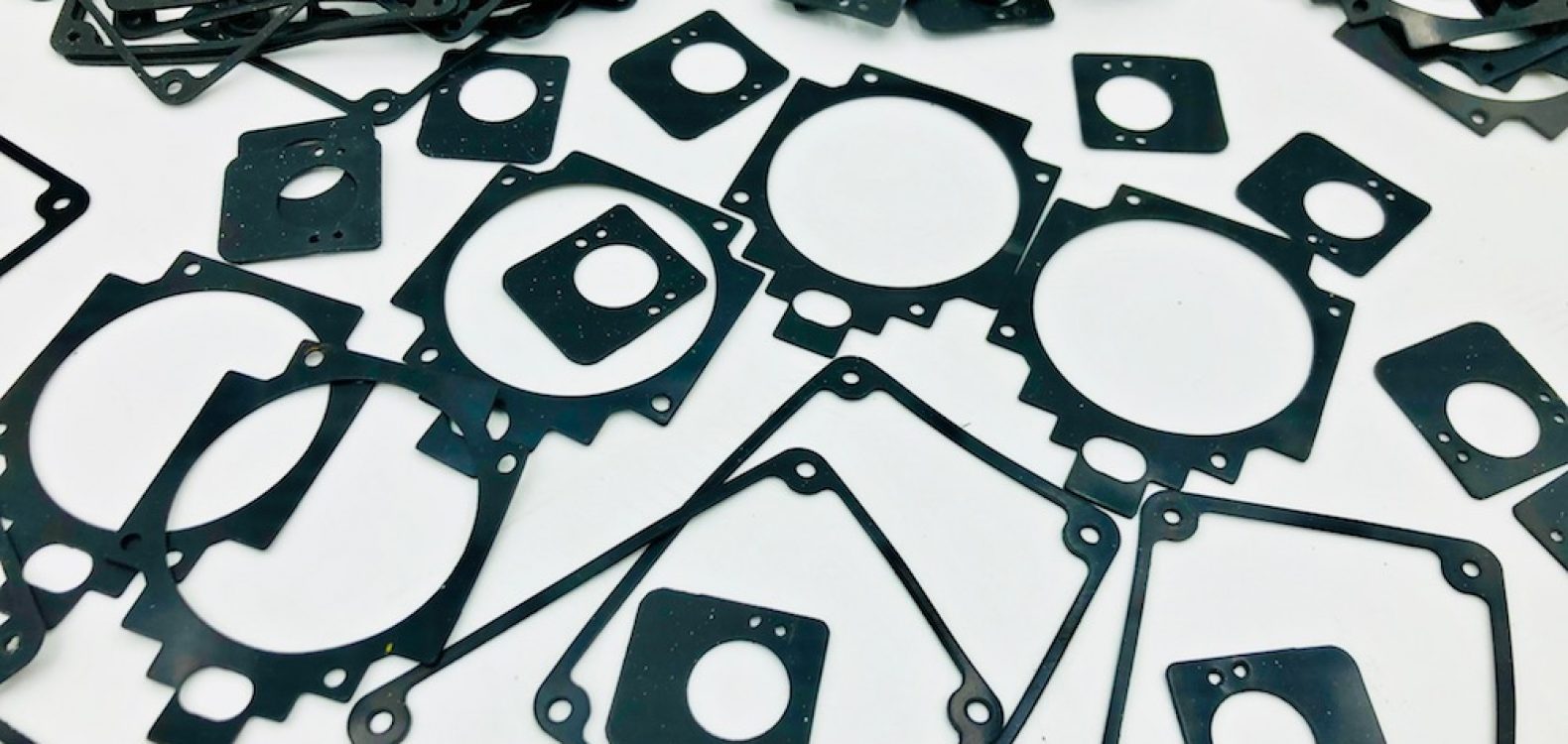

- Molding: The selected materials are molded into the desired seal shapes and sizes using compression or injection molding techniques.

- Quality Control: Rigorous quality control measures are implemented throughout the manufacturing process to ensure the seals meet industry standards and specifications.

Advantages of GRP Pipe Seals:

- Durability: GRP pipe seals are built to withstand harsh environmental conditions, ensuring a long service life.

- Cost-Effective: Their durability and resistance to corrosion result in reduced maintenance and replacement costs over time.

- Environmental Friendliness: GRP materials are recyclable and have a lower carbon footprint compared to traditional materials like steel.

- Lightweight: GRP pipe seals are significantly lighter than steel, making transportation and installation more manageable.

- Customization: These seals can be tailored to fit specific pipe dimensions and sealing requirements, enhancing their versatility.

In conclusion, GRP pipe seals play a crucial role in ensuring the functionality and longevity of GRP piping systems across various industries. Their resistance to corrosion, sealing efficiency, and adaptability make them a valuable component in fluid conveyance systems where durability and reliability are paramount. The widespread use of GRP pipe seals highlights their importance in modern infrastructure and industrial applications.