In the context of ships and maritime applications, “ship seals” can refer to several different types of seals and sealing systems that are crucial for maintaining the integrity and safety of the vessel. These seals are used to prevent leaks, maintain buoyancy, and ensure the overall seaworthiness of the ship. Below, we’ll explore some of the key types of ship seals and their functions:

- Hull Seals:

- Hull Penetrations: Ships have various openings or penetrations in the hull for items such as propeller shafts, rudder shafts, and cooling water intakes. Seals are used around these penetrations to prevent water from entering the hull and maintain buoyancy. These seals are often made of rubber or other elastomeric materials.

- Hatch Seals:

- Cargo Hatch Seals: Cargo hatches on cargo vessels must be sealed securely to prevent water ingress during transit. Hatch seals are typically made of rubber and are designed to create a watertight barrier when the hatches are closed.

- Shaft Seals:

- Propeller Shaft Seals: To prevent water from entering the ship through the propeller shaft, ships use seals such as shaft seals or stern tube seals. Common types include lip seals and mechanical seals, which provide a watertight barrier around the rotating shaft.

- Bulkhead Seals:

- Bulkhead Penetrations: Seals are used around bulkhead penetrations (where pipes, cables, or conduits pass through bulkheads or walls) to maintain watertight integrity, especially in areas where a breach could lead to flooding.

- Porthole Seals:

- Portholes and Windows: Seals are used around portholes, windows, and other openings in the ship’s superstructure to prevent water ingress, maintain visibility, and ensure the safety of passengers and crew.

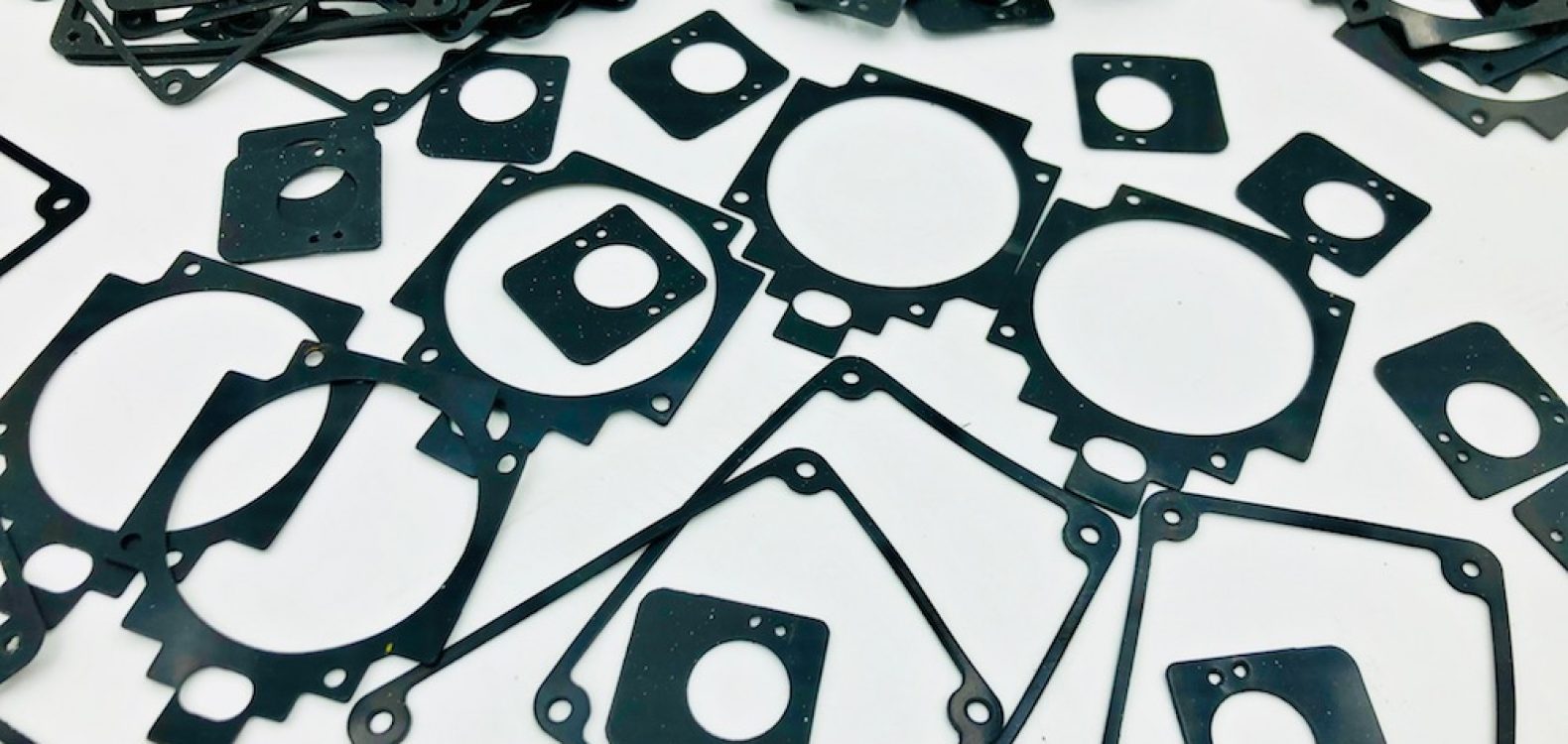

- Gasket Seals:

- Gaskets for Doors and Hatches: Gaskets are used on doors and hatches throughout the ship to create a tight seal when they are closed, preventing water, air, and noise from passing through.

- Lifeboat and Liferaft Seals:

- Seals on Lifeboats and Liferafts: The seals on lifeboats and liferafts are essential for maintaining their buoyancy and ensuring they remain afloat in case of an emergency.

- Bilge Pump Seals:

- Seals in Bilge Systems: Ships use bilge pumps to remove water that accumulates in the bilge area. Seals on these pumps and associated piping prevent water from re-entering the bilge once pumped out.

- Hydraulic Seals:

- Hydraulic Systems: Ships often use hydraulic systems for various functions, including steering, stabilizers, and cargo handling. Seals in hydraulic systems are crucial to prevent leaks and maintain system functionality.

- Cable and Pipe Penetration Seals:

- Cable and Pipe Penetrations: Ships have numerous cables and pipes that pass through bulkheads and other barriers. Seals around these penetrations are essential to prevent water ingress.

- Environmental Seals:

- Environmental Protection: In certain maritime applications, seals are used to protect the ship’s equipment and systems from harsh environmental conditions, such as saltwater exposure, extreme temperatures, and UV radiation.

The materials used for ship seals vary depending on the specific application and environmental conditions. Common materials include rubber, neoprene, silicone, and various elastomers, chosen for their durability, resistance to seawater, and ability to maintain a watertight seal.

Proper maintenance and regular inspection of ship seals are essential for the safety and seaworthiness of vessels, as failure of these seals can lead to flooding, reduced buoyancy, and other safety hazards. Ship operators and crews must ensure that all seals are in good condition and functioning as intended to prevent potential risks at sea.