Industrial seals, also known as industrial gaskets or sealing components, are essential mechanical elements used in a wide range of industrial applications to prevent the leakage of fluids, gases, or contaminants. These seals play a critical role in maintaining the integrity, safety, and efficiency of various industrial processes and equipment. In this extensive description, we will delve into the types, functions, materials, and applications of industrial seals.

Types of Industrial Seals:

- O-Rings: O-rings are one of the most common types of industrial seals. They are circular, ring-shaped seals typically made from rubber, elastomers, or thermoplastics. O-rings create a tight seal by fitting into a groove or a gland and are used in various applications, including hydraulic systems, engines, and pumps.

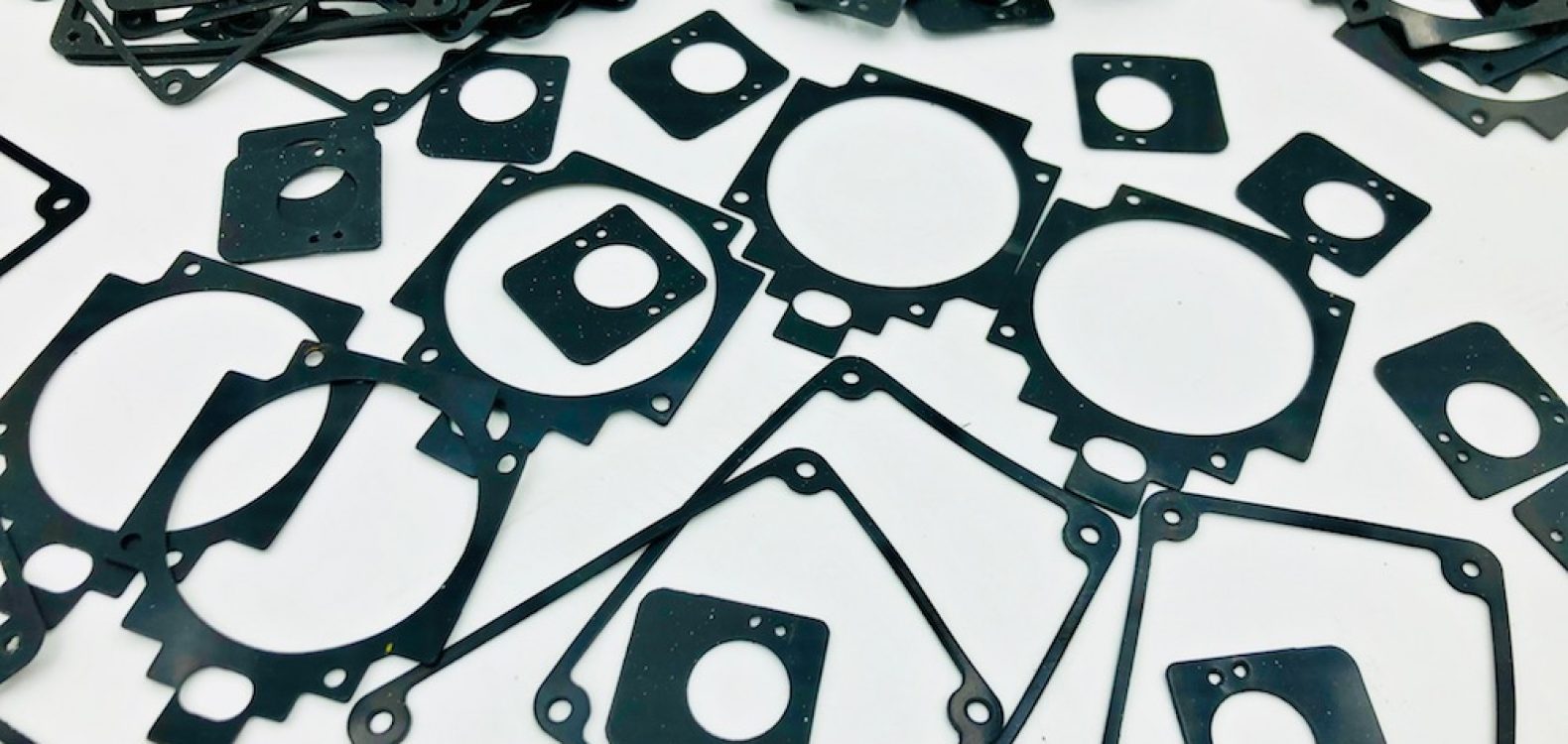

- Gaskets: Gaskets are flat or contoured seals placed between two mating surfaces to prevent the escape of gases or liquids. They come in a variety of materials, such as rubber, cork, metal, and composite materials, to suit specific industrial needs. Gaskets are used in flanges, pipes, and valves.

- Lip Seals (Oil Seals): Lip seals, often referred to as oil seals, are used to prevent the leakage of lubricants in rotating equipment, such as engines, gearboxes, and axles. They have a lip that contacts the rotating shaft, creating a dynamic seal.

- Mechanical Seals: Mechanical seals are used in rotating equipment to prevent leakage at the interface between a rotating shaft and a stationary housing. They consist of multiple components, including a stationary seat and a rotating seal face, to provide an effective dynamic seal.

- Hydraulic Seals: These seals are specifically designed for use in hydraulic systems, including cylinders and pumps. They come in various types, such as piston seals, rod seals, and wipers, to prevent fluid leakage and maintain system efficiency.

- Compression Packings: Compression packings are used in applications where a rotating or reciprocating shaft passes through a housing or chamber. They are made from materials like braided fibers, graphite, or PTFE and are compressed to form a seal.

- Diaphragms: Diaphragms are flexible seals used to separate two mediums, typically in applications like pumps, valves, and regulators. They are often made from rubber, elastomers, or synthetic materials.

- Sealing Washers: Sealing washers, also known as crush washers, are used to create a tight seal between a bolt and a surface. They are commonly used in hydraulic and pneumatic systems.

Functions and Benefits of Industrial Seals:

- Leak Prevention: The primary function of industrial seals is to prevent the escape of fluids, gases, or contaminants, ensuring the integrity of a system or equipment.

- Environmental Protection: Seals protect industrial equipment from environmental factors such as dust, moisture, and corrosive substances that can lead to equipment degradation or failure.

- Enhanced Safety: Properly functioning seals help maintain safe working conditions by preventing leaks that can pose safety hazards, such as chemical spills or fires.

- Energy Efficiency: Seals reduce energy wastage by preventing leaks in hydraulic and pneumatic systems, ensuring that the energy transferred remains within the system.

- Reduced Maintenance: Well-designed and durable seals can extend the lifespan of equipment and reduce maintenance costs.

Materials for Industrial Seals:

Industrial seals can be made from a wide range of materials, depending on the application’s specific requirements. Common materials include:

- Rubber and Elastomers: Natural rubber, silicone rubber, nitrile rubber, and fluorocarbon rubber (Viton) are frequently used for their flexibility and resilience.

- Metal: Stainless steel, carbon steel, and aluminum are used in metal gaskets and some mechanical seals for their strength and corrosion resistance.

- PTFE (Polytetrafluoroethylene): PTFE is known for its excellent chemical resistance and is used in various sealing applications, including gaskets and lip seals.

- Graphite: Graphite is often used in compression packings and gaskets for its high-temperature resistance and self-lubricating properties.

- Composites: Composite materials, which can combine rubber, fabric, and other elements, are chosen for their specific material properties, such as resistance to heat, chemicals, or wear.

Applications of Industrial Seals:

- Oil and Gas Industry: Seals are used in pipelines, valves, and drilling equipment to prevent leaks and ensure safety in the oil and gas sector.

- Automotive Industry: Automotive applications include sealing engine components, transmissions, and brake systems to prevent fluid leakage.

- Aerospace Industry: Aircraft and spacecraft employ seals in engines, landing gear, hydraulic systems, and fuel systems to maintain safety and performance.

- Manufacturing and Machinery: Industrial machinery, such as pumps, compressors, and conveyors, relies on seals to maintain efficiency and prevent contamination.

- Pharmaceutical and Food Processing: Seals are crucial in maintaining hygienic conditions in pharmaceutical and food processing equipment, ensuring product quality and safety.

- Chemical Industry: Seals are used in chemical processing equipment, valves, and reactors to prevent the escape of hazardous chemicals.

- Power Generation: Power plants use seals in turbines, boilers, and generators to maintain energy efficiency and prevent leaks.

- Marine and Shipbuilding: Seals are employed in ship systems, including propulsion, steering, and cargo handling, to ensure seaworthiness and safety.

In conclusion, industrial seals are indispensable components in various industries, ensuring the integrity and safety of equipment, preventing leaks, and promoting efficiency. Their diverse types, materials, and applications make them versatile solutions for maintaining operational excellence across a wide range of industrial processes and sectors. Proper selection, installation, and maintenance of industrial seals are essential to ensure optimal performance and safety.