A dilatation seal, also known as an expansion joint or expansion seal, is a specialized engineering component designed to accommodate and manage the relative movement and thermal expansion and contraction of different structural or mechanical elements within a system. These seals are used in various industries, including construction, infrastructure, automotive, aerospace, and manufacturing, to name a few, and play a crucial role in maintaining the structural integrity, safety, and functionality of the systems they are applied to.

The fundamental purpose of a dilatation seal is to provide a flexible and durable connection between adjacent parts or structures, allowing them to move independently while preventing the ingress of unwanted materials such as moisture, dust, or debris. This is especially important in situations where rigid connections might lead to structural damage, decreased efficiency, or safety hazards. Dilatation seals help mitigate the forces generated by thermal expansion and contraction, seismic activity, wind, vibrations, and other dynamic loads.

Key characteristics and features of dilatation seals include:

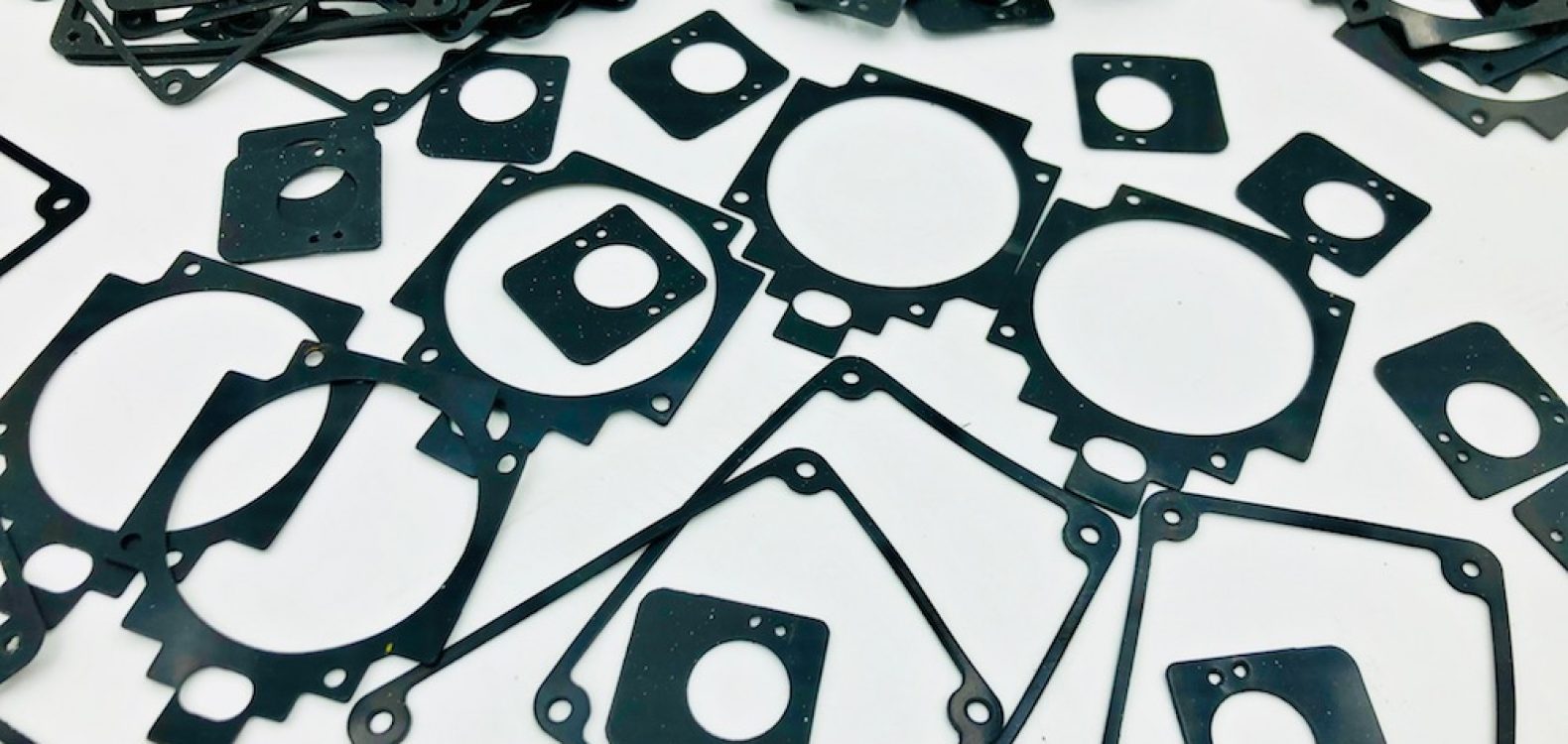

- Material Composition: Dilatation seals are typically made from various materials, depending on the application. Common materials include rubber, neoprene, elastomers, metals, or composite materials. The selection of material depends on factors such as the temperature range, chemical exposure, and mechanical properties required.

- Profile and Design: Dilatation seals come in various profiles and designs to accommodate specific movement requirements and environmental conditions. These profiles can be straight, curved, or angular, and the design might include reinforced edges, flanges, or anchors to secure the seal in place.

- Movement Capability: Dilatation seals are engineered to allow movement in multiple directions, such as axial (along the seal’s length), lateral (side-to-side), and angular (rotation or tilting). This flexibility enables them to adapt to complex movement patterns.

- Size and Dimensions: These seals come in a range of sizes to suit different applications, from small joints in concrete pavements to large gaps in bridges, buildings, or pipelines.

- Load-Bearing Capacity: Some dilatation seals are designed to bear heavy loads, making them suitable for use in high-traffic areas or industrial settings. They can support the weight of vehicles, equipment, or structural components.

- Environmental Resistance: Dilatation seals are often exposed to harsh environmental conditions, so they must be resistant to weathering, UV radiation, chemicals, and extreme temperatures to ensure their longevity and performance.

- Installation and Maintenance: Proper installation is critical to the effectiveness of dilatation seals. Regular maintenance is also essential to ensure that they continue to function as intended over time. This may involve inspections, cleaning, and, if necessary, replacement.

- Sealing and Water Resistance: In many applications, dilatation seals need to provide an effective barrier against water infiltration. The sealing properties of these joints are crucial, especially in structures like bridges and dams.

- Fire Resistance: In some cases, dilatation seals are required to meet fire-resistance standards to prevent the spread of flames and smoke in the event of a fire.

- Standards and Codes: The design, manufacture, and installation of dilatation seals may need to adhere to specific industry standards and codes, ensuring that they meet safety and performance requirements.

Common applications of dilatation seals include:

- In construction for sealing joints in buildings, bridges, and highways.

- In industrial settings to accommodate movement in pipelines, ducts, and tanks.

- In automotive manufacturing for vehicle body panels and exhaust systems.

- In aerospace for sealing joints in aircraft components.

- In HVAC systems to manage expansion and contraction in ductwork.

Dilatation seals are a vital part of ensuring the longevity, safety, and functionality of various structures and systems across different industries. Their flexibility, durability, and ability to adapt to a wide range of environmental conditions make them indispensable components in modern engineering and construction.