Aluminum rubber, or sometimes referred to as “aluminum-rubber composite,” is a material that combines aluminum and rubber elements to create a composite material with specific properties and applications. This composite material typically consists of a layer of rubber or elastomer bonded to a layer of aluminum or aluminum alloy. The combination of these two materials imparts a range of advantages and characteristics suitable for various industrial and engineering applications.

Key Features and Properties of Aluminum Rubber Composite:

- Lightweight: Aluminum is inherently lightweight, and when combined with rubber, the resulting composite retains this property. This makes it useful in applications where weight reduction is critical.

- Vibration Damping: The rubber layer in the composite provides excellent vibration damping and shock absorption properties, making it suitable for applications where noise and vibration control are essential.

- Thermal Insulation: Rubber offers thermal insulation properties, which can be beneficial in applications requiring temperature control and heat resistance.

- Corrosion Resistance: Aluminum is naturally resistant to corrosion, making the composite suitable for use in corrosive environments.

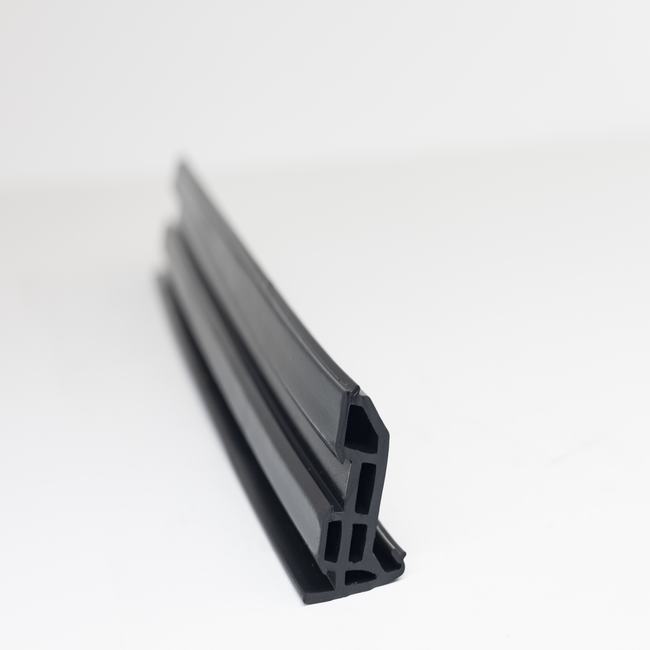

- Flexibility: The rubber layer adds flexibility to the material, allowing it to conform to irregular shapes and surfaces.

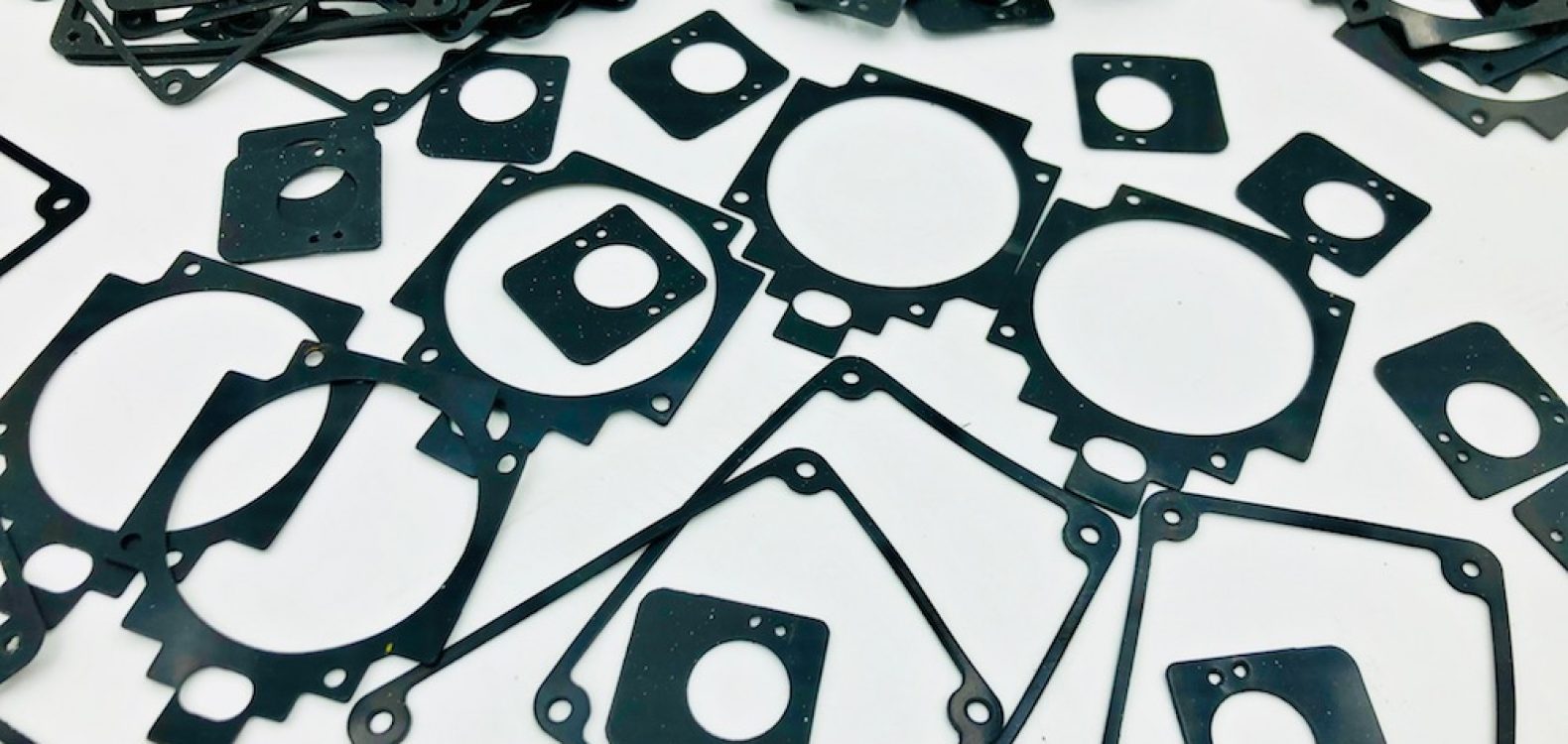

- Sealing Properties: Aluminum rubber composites can serve as effective sealing materials, preventing the ingress of moisture, dust, and other contaminants.

Applications of Aluminum Rubber Composites:

- Automotive Industry: Aluminum rubber composites are used in automotive suspension components, engine mounts, and vibration isolation systems to reduce noise and vibrations.

- Construction: They find applications in construction as vibration isolators for machinery, noise barriers, and sealing materials for building joints.

- Aerospace: In aerospace, these composites are used for vibration and shock isolation, as well as in components that require lightweight yet durable materials.

- Electronics: They are used in electronic equipment to dampen vibrations and reduce electromagnetic interference (EMI) and radiofrequency interference (RFI).

- Industrial Machinery: Aluminum rubber composites are employed in various industrial machinery to reduce noise, protect components from shocks, and isolate vibrations.

- Marine: In the marine industry, they are used for mounting equipment and machinery on ships to dampen vibrations and reduce noise.

- Renewable Energy: These composites are used in wind turbines to reduce vibrations and improve the performance and longevity of turbine components.

- Manufacturing: They can be used as shock mounts for delicate instruments and machinery in manufacturing environments.

The specific properties and applications of aluminum rubber composites can vary based on the formulation and design of the material. Manufacturers can tailor these composites to meet the requirements of specific industries and applications, making them versatile materials for solving a range of engineering challenges.