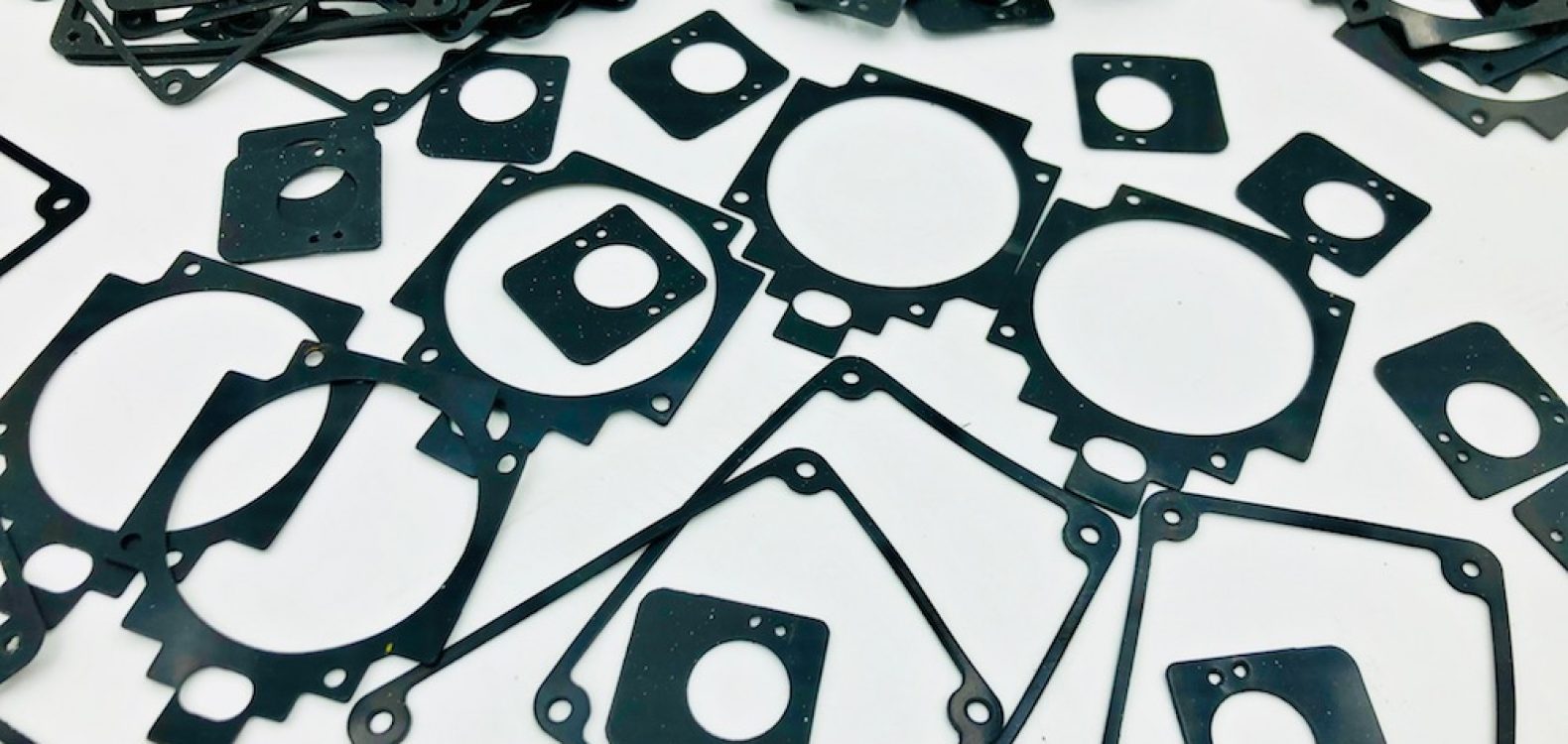

EPDM (Ethylene Propylene Diene Monomer) rubber seals, often simply referred to as EPDM seals, are a type of elastomeric sealing component made from EPDM rubber material. EPDM rubber is known for its excellent resistance to weathering, UV radiation, ozone, and a wide range of chemicals, making it a popular choice for sealing applications in various industries. EPDM rubber seals are used to provide watertight, airtight, and weatherproof seals in a variety of applications. Here, we’ll explore the key features, applications, and benefits of EPDM rubber seals.

Key Features of EPDM Rubber Seals:

- Weather Resistance: EPDM rubber is highly resistant to weathering, making it suitable for outdoor and exposed applications. It can withstand temperature extremes and prolonged exposure to sunlight without degradation.

- Chemical Resistance: EPDM rubber exhibits good resistance to a wide range of chemicals, including acids, alkalis, and some solvents.

- Waterproofing: EPDM rubber is known for its excellent waterproofing properties, making it effective for sealing against moisture and water ingress.

- Flexibility: EPDM rubber is highly flexible and elastic, allowing seals to conform to irregular surfaces and maintain their seal even under dynamic conditions.

- Durability: EPDM rubber seals have a long service life and are resistant to cracking, tearing, and abrasion.

- Electrical Insulation: EPDM rubber is an effective electrical insulator, making it suitable for electrical enclosure gaskets and insulation applications.

Applications of EPDM Rubber Seals:

- Automotive Industry: EPDM rubber seals are used in automotive applications, including door seals, window seals, trunk seals, and gaskets for engine components.

- Construction: EPDM rubber seals are used in building construction for sealing windows, doors, curtain wall systems, and roofing systems to prevent air and water infiltration.

- HVAC Systems: They are employed in heating, ventilation, and air conditioning (HVAC) systems to seal ducts, pipes, and access panels, ensuring air and water-tightness.

- Electrical Enclosures: EPDM rubber gaskets provide environmental sealing for electrical enclosures, protecting sensitive electronics from moisture and dust.

- Marine Industry: EPDM rubber seals are used in boats and marine equipment to provide watertight seals for hatches, doors, and windows.

- Aerospace: They are used in aerospace applications for sealing and insulating various components in aircraft and spacecraft.

- Industrial Equipment: EPDM rubber seals are used in industrial machinery, pumps, and valves to prevent leaks and provide sealing in chemical processing and other applications.

- Solar Panels: EPDM rubber gaskets are used in photovoltaic systems to seal and protect solar panels from environmental factors.

- Food and Beverage Industry: EPDM rubber seals are suitable for use in food and beverage processing equipment due to their resistance to food-grade chemicals and temperatures.

Benefits of EPDM Rubber Seals:

- Reliable Sealing: EPDM rubber seals offer excellent sealing properties, preventing the ingress of air, water, and contaminants.

- Longevity: EPDM rubber has a long service life and maintains its properties over time, reducing the need for frequent replacements.

- Energy Efficiency: By sealing gaps and preventing air infiltration, EPDM rubber seals contribute to energy efficiency and reduced heating and cooling costs.

- Environmental Resistance: EPDM rubber seals are highly resistant to environmental factors, making them suitable for both indoor and outdoor applications.

- Easy Installation: They are easy to install and can be custom-cut to fit specific dimensions and shapes.

In summary, EPDM rubber seals are versatile sealing solutions used in various industries and applications where resistance to weathering, temperature extremes, chemicals, and moisture is essential. Their durability, reliability, and adaptability make them a popular choice for sealing and insulating purposes in diverse environments.